WASTEWATER REMEDIATION GAME CHANGER

The Rare Earth Farm, (TREF)

A minority-owned company, TREF is dedicated to harvesting and marketing organic products derived from rare volcanic rock. Our vision is to be a transformative force, improving lives by harnessing the natural abundance of volcanic rock and the expertise of our talented team. Our latest innovation—an independently tested, organic Volcanic Rock (VR) solution—embodies this vision.

Wastewater Management Redefined

Wastewater management is critical for maintaining clean water systems, protecting ecosystems, and safeguarding human health. Traditional chemical treatments, while effective, often introduce new environmental risks. pH72® VR offers a natural, sustainable alternative that enhances filtration, reduces chemical dependence, and promotes long-term environmental sustainability.

DOWNSIDES OF STANDARD CHEMICAL TREATMENTS

Common wastewater treatment methods rely on chemicals like chlorine, alum, ferric chloride, and lime. While effective, these substances come with significant environmental and operational drawbacks.

Current Wastewater Treatment Methods:

• Harm to Aquatic Ecosystems: Chemical runoff can disrupt ecosystems, harming wildlife and water quality.

• Reduced Farmland Nutritional Value: Residual chemicals diminish soil fertility, impacting agricultural productivity.

• Increased Operational Costs and Inefficiencies: The use of chemicals raises costs, requires specialized handling, and often results in inefficient long-term processes.

IMPACT OF CHEMICAL CONTAMINANTS ON ECOSYSTEMS

Chemical Residues

Disinfection chemicals like chlorine leave behind harmful byproducts such as trihalomethanes (THMs), which accumulate in rivers, lakes, and oceans. These residues disrupt aquatic ecosystems and enter the food chain.

Algae Blooms and Oxygen Depletion

Chemical runoff creates nutrient imbalances, triggering algae blooms. As algae decompose, they deplete oxygen levels, create dead zones, and block sunlight— severely disrupting marine ecosystems.

Long-Term Soil and Water Contamination

Chemical treatments not only affect water bodies but also contaminate soil and groundwater. This degrades soil quality, disrupts the microbiome, and renders land unsuitable for agriculture or safe drinking water.

CHALLENGES IN CHEMICAL TREATMENT OPERATIONS

Operational Challenges

Handling and applying chemicals such as chlorine requires specialized equipment and training, which increases operational costs, poses safety risks, and heightens the potential for environmental disasters like spills.

Corrosion and Infrastructure Damage

Corrosive chemicals, like ferric chloride, accelerate infrastructure degradation, leading to higher maintenance costs and more frequent repairs or replacements.

High Energy Costs

Chemical treatments require significant energy input, increasing operational carbon footprints and hindering sustainability efforts in wastewater management.

THE SOLUTION –pH72® VR

An environmentally friendly approach that enhances water quality, reduces costs, and supports sustainability.

THE NATURAL FILTRATION SOLUTION

VR offers a proven, chemical-free method to purify water and restore soil, effectively neutralizing heavy metals, PFAS, and other contaminants. This reduces environmental risks while delivering health and economic benefits. By adopting

VR's sustainable solution, communities and organizations not only enhance water and soil quality but also position themselves as leaders in environmental stewardship, driving long-term value and unlocking opportunities for meaningful change.

HOLISTIC APPROACH TO WASTEWATER MANAGEMENT

The use of pH72® VR offers a forward-thinking, eco-friendly alternative to chemical-based wastewater treatments, allowing facilities to implement a natural filtration system.

Key Benefits:

• Protect Local Ecosystems: Prevent harmful chemical residues and pollution from affecting local environments.

• Promote Safer Operations: Minimize reliance on hazardous chemicals, reducing safety risks for operators.

• Support Sustainability: Align with environmental goals by decreasing chemical usage, carbon footprints, and water wastage.

• Enhance Water Quality: Improve water quality without introducing new environmental hazards, benefiting both human populations and natural habitats.

• No Harmful By-Products: Eliminate contaminants without adding new chemicals, preserving waterway and marine life health.

• Support Biodiversity: Maintain neutral pH levels and filter out toxins to protect aquatic life and foster a diverse, resilient ecosystem.

• Facilitate Sustainable Agriculture: Safely reuse VR-treated water for agriculture and non-potable purposes, promoting sustainable farming and reducing pressure on natural water resources.

ENVIRONMENTAL & OPERATIONAL BENEFITS

• Simplified application process

• Reduced maintenance and labor costs

• Enhanced safety for operators

• Strong inventory and reliable supply chain

• Improves the health of rivers and streams

• Enhances the nutritional value of farmland

• Supports sustainability goals

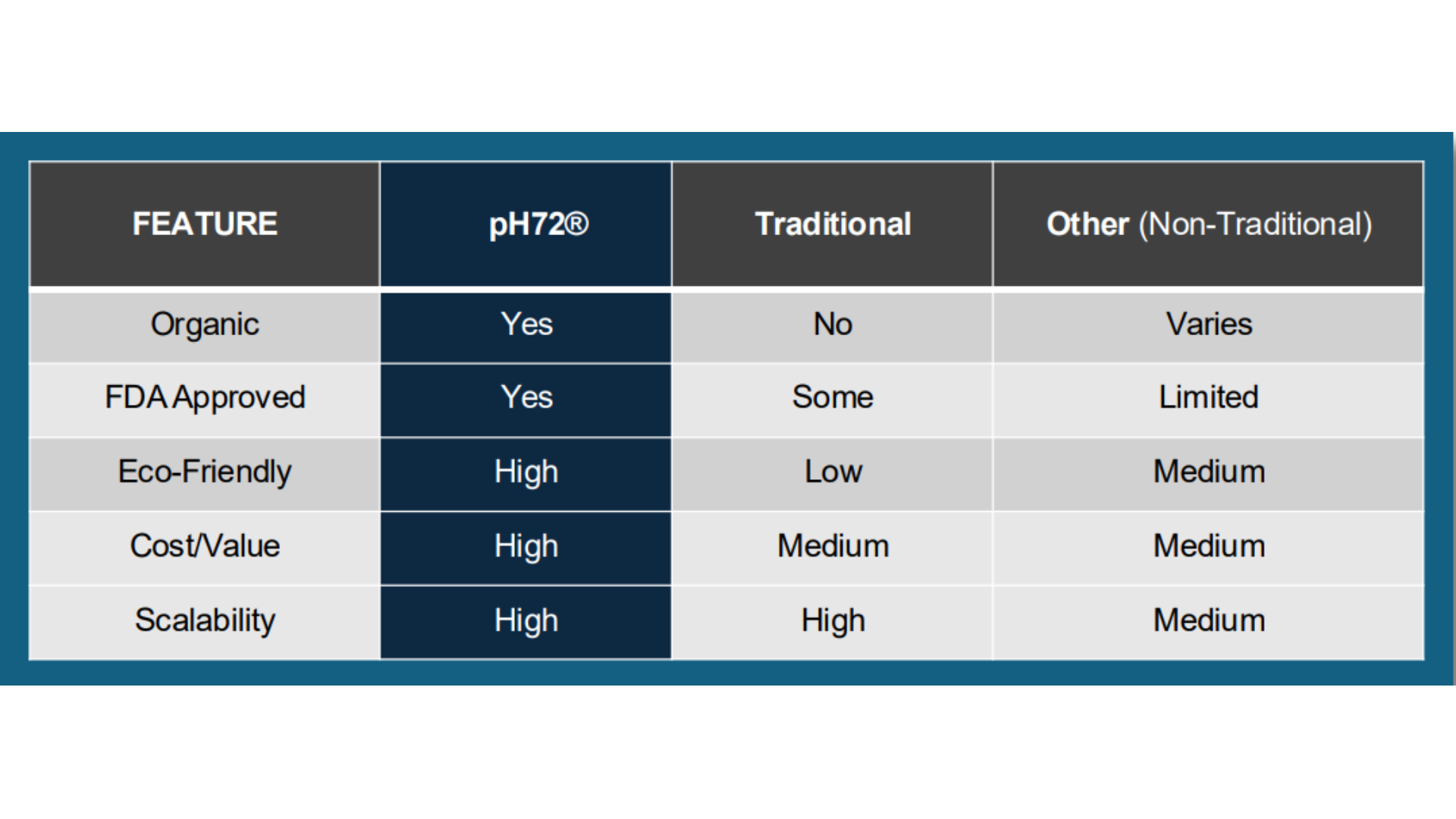

VR OUTPERFORMS TRADITIONAL METHODS

Non-Chemical Filtration

pH72® utilizes VR's natural properties to filter wastewater, effectively binding and removing heavy metals and pollutants without introducing harmful chemical residues, thereby protecting local water ecosystems.

Simplified Application and Reduced Maintenance

pH72® streamlines wastewater management by minimizing chemical dosing and complex monitoring while eliminating special handling requirements, thus reducing maintenance costs, lowering accident risks, and prolonging the lifespan of treatment systems.

Operational Efficiency and Safety

Using pH72® simplifies wastewater treatment operations, enhancing safety and costeffectiveness while minimizing manual interventions, chemical storage needs, and environmental risks, all of which contribute to longterm sustainability by reducing energy consumption and carbon emissions.

Sustainable and Environmentally Friendly

By eliminating chemicals, pH72® reduces the environmental impact of wastewater treatment, ensuring cleaner water discharge without harmful byproducts, promoting water reuse in agriculture and industry, and conserving freshwater resources.

Improved Water Quality and pH Stability

A key advantage of pH72® is its natural ability to stabilize water pH levels through the 72 essential minerals in VR, which supports aquatic life, enhances water quality, and reduces the risk of acidification in waterways.

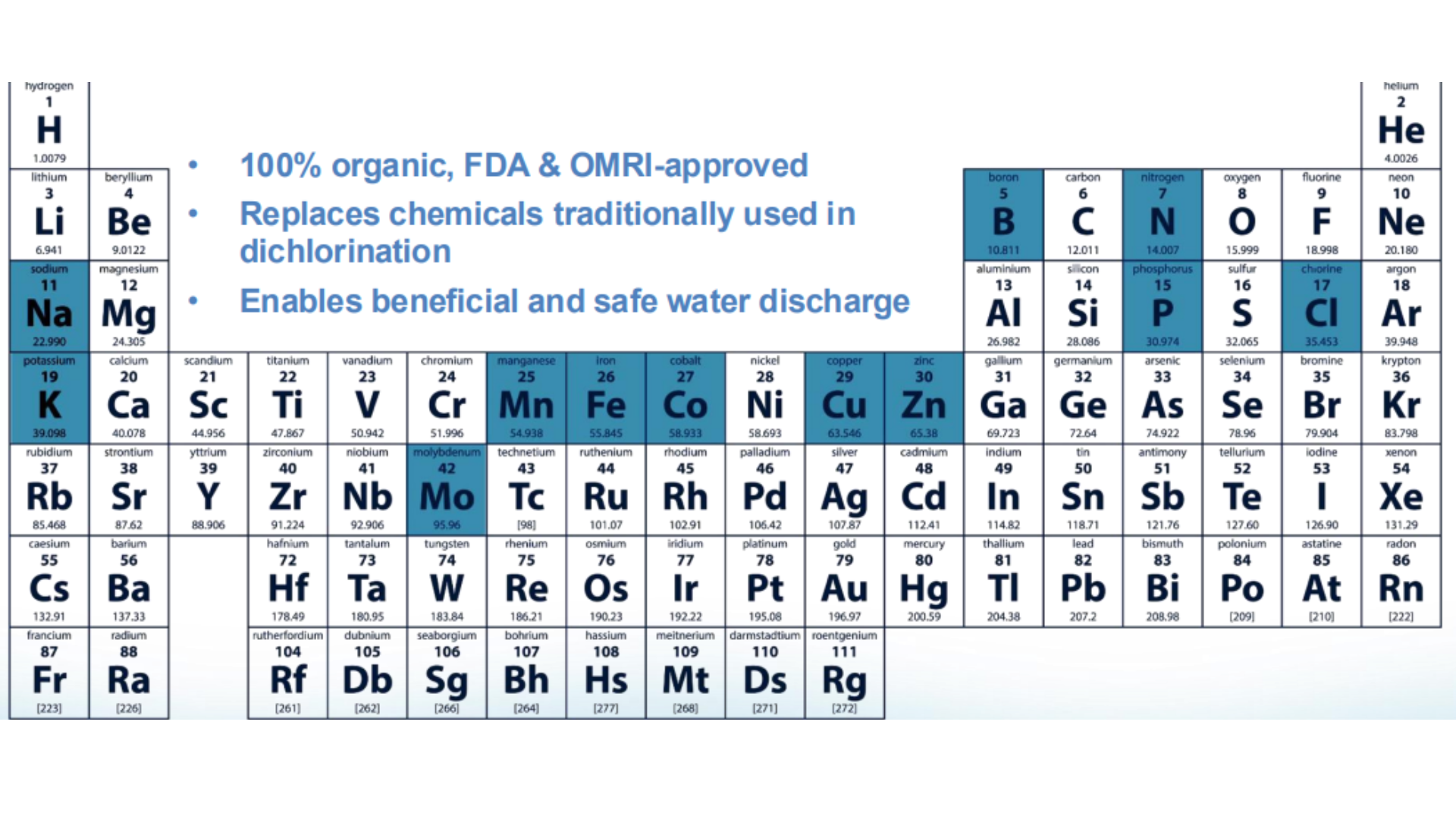

pH72® vs. COMPETITORS

WHY VR

A Proven Solution with Immediate Impact

Independently validated by industry leaders, VR effectively stabilizes water quality, protects soil, and enhances crop yields, enabling immediate action to reverse environmental damage.

Building a Legacy of Sustainability and Health for Future Generations

Supporting VR not only addresses current challenges but also fosters a sustainable future, resulting in cleaner water, healthier soil, and safer environments that promote better health for future generations and strengthen community resilience.

WHY YOU SHOULD GET INVOLVED

Scientific Integrity and Credibility

Understanding the science behind this issue reveals that effective solutions must be grounded in proven, natural methods, and VR offers a validated, practical approach that has already demonstrated results, enabling the scaling of this technology.

A Platform for Advocacy

Amplifying the message that access to clean water and sustainable solutions is a global issue requires influential voices to advocate for fairness and equity that benefits all of humanity.

Aligning Science and Social Justice

This initiative transcends scientific advancement, emphasizing social justice by demonstrating how support for VR can connect technical innovation with meaningful impact, showcasing science as a catalyst for creating a safer and healthier ecosystem.

VALIDATED PERFORMANCE

• Proprietary formulation backed by extensive research

• Positive results confirmed by global consultants

• Ongoing commitment to independent testing

NATURE’S MINERAL POWERHOUSE

Independent Test Conducted on August 12, 2024

Proven efficacy in bringing pH to the appropriate alkaline level before discharge.

We concluded that treating a minimum of 340 million gallons of wastewater per day requires applying one metric ton (MT) of VR per 20 million gallons treated. Many of the facilities we consult apply between 6-15 inorganic chemicals daily. Based on this, we recommend that 25% of the chemical treatment incorporate VR to ensure complete chlorine removal from the discharge water. Throughout our enrichment process, we apply one MT of VR to each phase—primary, secondary, and tertiary—due to VR's porosity.

APPLICATION

One metric ton per 20 million gallons in the Primary, Secondary, and Tertiary stages.